By Faraz Khalid, Product Manager, at Commsoft OASES

Our newly arrived Head of Product, Faraz Khalid, has spent almost 15 years working on a wide spectrum of disciplines including maintenance planning, engineering services, line and base maintenance, resource and materials management, reliability programs, technical records management, and data analytics.

Here he outlines his vision for the next phase of essential digitization for our MRO customers, and the developments he is heading up to make sure OASES software

meets the leadership expectations the industry has of us.

More data, less margin for error

The pressing need for any CAMO, national carrier, or independent operator in today’s world is to optimize resources and minimize costs. In other words, to find reliable ways to do more with less.

The drive is not to cut costs, but to reduce waste. This is about becoming more time-efficient, managing inventory to avoid having cash tied up in a warehouse, and planning diligently to avoid gaps in maintenance schedules and delays in turnaround. Cost reductions follow when such actions are implemented.

Through any of these endeavors, the successful organization is one that has unwavering confidence about the processes it adheres to. It exercises unequivocal observance of the compliance it is subject to— such as EASA’s[1] Part M and Part 145 — and has 100 percent certainty in tools it uses to enable the efficiencies it aspires to.

Confidence and certainty derive in large measure from an organization’s preparedness to embrace data, and the importance of making it a central driving force in their operations.

Data-centricity is very much our focus at OASES as we now lay the foundations for our development roadmap. We will be involving our customers in the process to make sure that our modules—and the digitized MRO workflows they facilitate—address the very real needs and pressures that beset them in the industry today.

My contact details are the bottom of this blog if you want to share your own observations or needs with the OASES team.

The digitization principle: Optimum Efficiency in MRO

‘Doing more with less’ has always been a core principle in defining organizational success (and profitability)—and a critical pillar in technologies designed to help you achieve such goals. Yet I find that many organizations lean more towards a mid- to long-term vision relative to modernizing their operations, rather than accepting the need for expediency, if not actually for urgency.

Why digitize? Four quick checks to assess the need

If you believe that your maintenance, repair, and overhaul procedures and operations are running at top level efficiency, you will probably already have validated their performance against the parameters below. If you feel there is scope for improvement, then you may find it beneficial to audit your practices, answering these questions:

- Are you running Best Practice MRO?

While it is perfectly rational to stick with tried and tested processes for planning, maintenance control, materials management and even continuing airworthiness activities, it is not necessarily best practice. Just because it works, does not mean there is no scope for improvement. - Have you identified weak links?

If your approach to these and other tasks is, indeed, ‘tried and tested’ then you may be inclined to make the assumption that time is on your side. The flipside of that assumption is that you may now well be running below optimum efficiency; without even knowing it.

Do your teams communicate every action as it happens? Does compliance pervade every process? Are robust audit trails maintained to validate and demonstrate your processes? - Do you exploit resources to their fullest?

“Today’s world” is different to what it was when you first put those existing approaches, or processes, into action. It is probably different to what it was when you last revised them. It is also completely different to what it was just a few short years ago when the global pandemic changed many perspectives in many industry sectors, and put a spark of urgency into digital transformation.

Have you managed changing workforce scenarios, and realigned management and reporting procedures accordingly? - Do you manage information, or just use it?

If your teams are still using paper-based processes it would suggest that you are simply using information. Engineers may check their work orders, complete the tasks and record the interventions; then passing the information back to the main office for someone else to log and record. There is a time-lag in all of this. There is a possibility of human error. There is a chance that busy people forget to complete paperwork, or that schedulers run into clashes due simply to sheer weight of tasks.

Managing information is different to just using it. ‘Managing’ is when the holistic value of information is leveraged constantly, in real-time; when one action informs the next, and daily routines inform future schedules; when inventory ties in precisely to parts call-off, and when audit trails are automatically created.

This is data-centricity. It is the underpin of transforming efficiencies and reducing waste, while ensuring compliance and safety, resource optimization and workforce productivity. As it does all this, data-centricity also motivates people—they feel in control.

Find the gaps, and fill them

Answering the questions above is about finding where gaps may exist in how you do things now, as opposed to how you can consider doing them better in the future. It’s the start of a Gap Analysis. That’s exactly what we are undertaking at OASES to ensure our solutions address your needs.

Artificial Intelligence (AI), Machine Learning (ML) and Business Intelligence (BI) are being embedded in our solutions. These are the technologies that enable you to manage information— to share data in real -time, every step of every process. They enable control in a way that paper-based systems never can, and that many legacy solutions in use today in MRO rarely do.

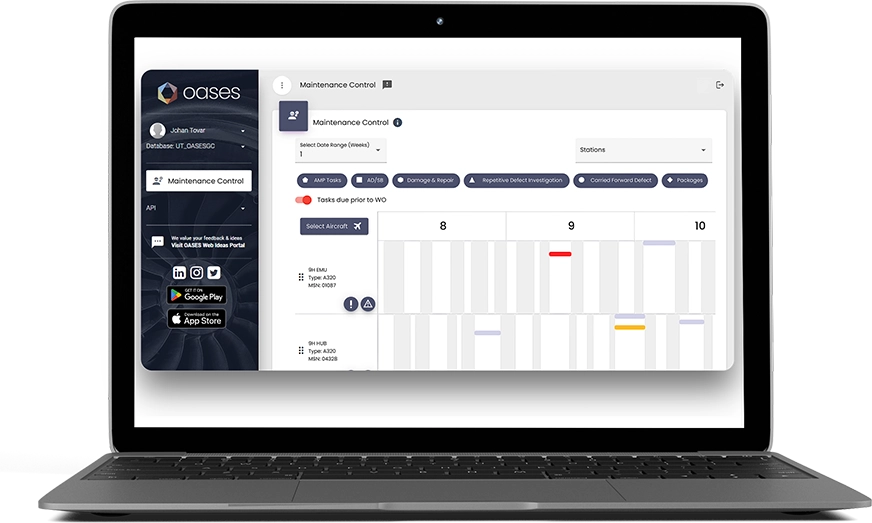

OASES Cloud is already empowering 130 aviation organisations; national carriers, large third-party maintenance providers, and independent operators. It makes sure that they have the latest technology at the heart of the operations without their having to continually monitor the market to evaluate fresh innovation. It keeps them current, informed, and efficient through a single cloud-based data repository—the source of basically everything their teams need to know when they need to know it.

OASES Mobile is saving teams time, streamlining their workflows, and increasing productivity because no one ever has to scramble around to check schedules or report back. They are in touch, connected, and informed.

And now, the future

Now we look to enhance the capabilities that OASES delivers. We are looking at data visualization enhancements because making sense of data can often be challenge to busy teams. We are looking at extracting further value for customers from AI, ML, and BI functionality because there is no end to the ways in which data can be sliced and diced to provide more insights in every corner of the MRO process. We are looking ever more closely at roles-based functionality, because the complexities of each role do not always overlap, and the requirements of software and data must be finely attuned to be at all times relevant and of practical use to each user.

That’s my role, to garner the frontline expectations of our customers and the industry and marry them to the talents and insights of our developers. We’re on the next stage of the journey and look forward to having you along with us. I’ll be exploring more in my next blog and hope to hear from you in the meantime.

Feel free to connect with me on LinkedIn, or just email me at: [email protected]

Source – [1] EASA | European Union Aviation Safety Agency

To learn more or book an OASES demo, contact us today

For organisations looking to ascend to new heights of operational excellence, contact us today to book a demo.