The aviation industry is increasingly focusing on sustainability as environmental concerns become more pressing. In fact, according to a report by KPMG, both MRO and ground handling should see a 50% reduction in emissions intensity by 2050. But how will we get there?

Among the various efforts underway to make aviation greener – including SAFs, the design of sustainable aircraft, electrifying ground vehicles, and using renewables to power maintenance facilities – streamlining MRO processes also makes a difference.

We consider OASES to be a vital key to this transformation. Read on to find out how it takes MRO sustainability to new heights.

The Role of MRO in Sustainable Aviation

Maintenance, Repair and Overall can involve significant resource use and waste. Below are several activities which – if conducted efficiently – have the potential to improve sustainability outcomes.

Extending Aircraft Lifespan

Through regular maintenance and timely repairs, MRO ensures that aircraft remain operational for longer, thus delaying the environmental impact associated with manufacturing new aircraft (from production processes and the use of raw materials).

Recycling, Reusing, and Improving Inventory Management

Sustainable MRO practices increasingly involve the recycling and reuse of aircraft parts, as well as optimising the efficiency of logistics and inventory management.

In fact, according to Lufthansa Technik, the industry has 30-40% excess inventory, with many parts being shelved and becoming obsolete.

Some operators are also working with suppliers to better consolidate shipments, reducing direct and indirect emissions.

Enhancing Fuel Efficiency

Of course, MRO activities often focus on maintaining and improving the fuel efficiency of aircraft through regular engine checks, and repairs that ensure all components are functioning optimally. Effective MRO scheduling maximises the benefits of such activities.

Reducing Ground Operations Emissions

As well as optimising fuel use in-flight, MROs have the potential to optimise ground operations to be more eco-friendly. As mentioned, this involves the use of electric or hybrid ground service equipment, but improving scheduling is just as important (and may also reduce energy use in hangars and other maintenance facilities).

So, how exactly can operators get the most from the opportunities listed above? This is where advanced MRO software like OASES comes into play.

How is OASES Driving Sustainability in MRO?

OASES is built on cutting-edge technologies that streamline MRO processes, reducing waste and increasing efficiency.

Digitisation

OASES transforms traditional, paper-based maintenance operations into digital workflows. This not only cuts down paper waste but also enhances the accuracy and speed of maintenance activities, providing technicians and other personnel with all the information they need in one, easy-to-access place.

Techlogs, work orders, and all the documentation involved with commercial management are securely stored in a centralised system, providing a single source of truth for all users.

More Effective Scheduling

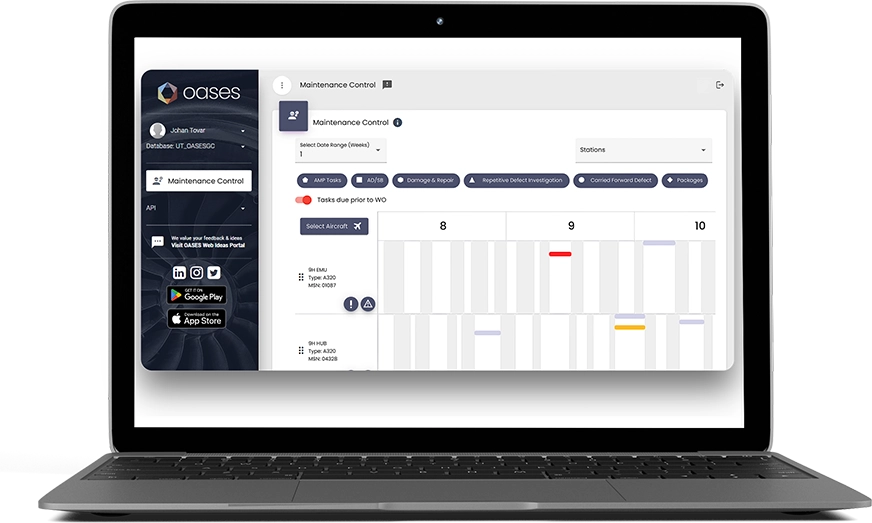

As mentioned, efficient scheduling helps reduce ground level emissions and ensures aircraft operate in the most fuel-efficient condition at all times. OASES optimises scheduling thanks to the modules below.

The Production Module

This provides real-time visibility into task status and material and resource use. In fact, users can plan the allocation of resources from hangar to individual task level, while bar-coding is used on work cards to capture work-in-progress data.

The Planning Module

This is where maintenance is forecast, with work package documentation and material pre-loads being generated automatically. The module also provides tools for tracking tasks in detail. Essentially, it relieves maintenance managers of many crucial, detailed yet repetitive tasks.

The Line Maintenance Module

This module lets you improve short-term maintenance planning by taking in data directly from EFB, ETL, e-enabled aircraft, and electronic operations systems. Staff can manage all short-term tasks from a single screen, while integration with our materials management module brings added efficiency.

Predictive Maintenance

With real-time data enabling predictive analytics, maintenance needs are accurately forecasted. This helps prolong the lifespan of parts and minimises fuel consumption, as aircraft are operating in their best condition at all times. (What’s more, Deloitte states that a predictive approach reduces maintenance costs by 25%, on average.)

Resource Optimisation

Through enhanced inventory management, OASES ensures that parts and materials are used more efficiently, reducing waste and excess. The software can forecast part demand, minimising overstocking and underutilisation, and may indirectly reduce emissions across the supply chain by improving logistical efficiency.

Demonstrating Compliance

With stricter regulation comes a greater compliance burden. Thus, airlines, MROs and CAMOs need effective ways to document their activities for auditing purposes. That’s exactly what OASES provides – granular reporting is conducted across the solution’s modules, automatically providing a robust audit trail.

Cloud Based Efficiency

Using cloud technology, OASES eliminates the need for extensive on-site IT infrastructure, which considerably reduces energy consumption (especially since old servers may not be designed with energy efficiency in mind).

Cloud solutions ensure that data and systems are accessible remotely, reducing the carbon footprint associated with commuting and on-site activities.

Conclusion

The role of MRO in sustainable aviation is multifaceted and increasingly vital as the industry seeks to minimise its environmental impact on all fronts – while meeting growing global travel demands.

OASES is at the forefront of this transition. Airlines, MROs and CAMOs across six continents use our solutions to cut costs, stay compliant, drive efficiency, and give back to the planet.

For a detailed look at exactly how it can help you do the same, contact us today to request a demo.