Globalisation has brought about new challenges that make aviation maintenance increasingly complex. The increased demand for air travel has put pressure on maintenance operations, and airlines need to meet ever-tighter schedules – all while ensuring compliance across borders. In addition, as emissions increase with every new route, the pressure to meet sustainability regulations mounts.

This article explores the challenges of globalisation in aircraft maintenance and the role technology has in conquering them.

The Challenges of Globalisation

Globalisation has created a more interconnected world, with people and goods travelling across the globe at unprecedented rates. In fact, the number of scheduled passengers boarded by the global airline industry in 2004 was 1,994 million; in 2019, it had reached 4,543 million (Statista).

The aviation industry has benefited from this trend (combined with the increase in freight due to the globalised economy), but it has also led to increased pressure to keep aircraft flying safely and efficiently. Things brings us to the next challenge – compliance. Each country has its own set of regulations and standards that airlines must adhere to.

Supply chain management is another challenging area when operating at global scales. Organisations may rely on suppliers from different territories to provide parts and services, creating a complex web of relationships that can be difficult to manage, particularly when it comes to ensuring quality and timely delivery.

Finally, there’s the matter of sustainability. With every new route and flight added to an airline’s schedule comes increased emissions. How can operators curb these emissions while keeping up with global demand? While there is no current alternative fuel used in aviation (at least not for everyday operations), modern technologies present a few tactics for optimising fuel usage.

How Technology Supports Global Aviation Maintenance

Technology is transforming aircraft maintenance, enabling airlines, MROs, and CAMOs to perform more efficiently and effectively.

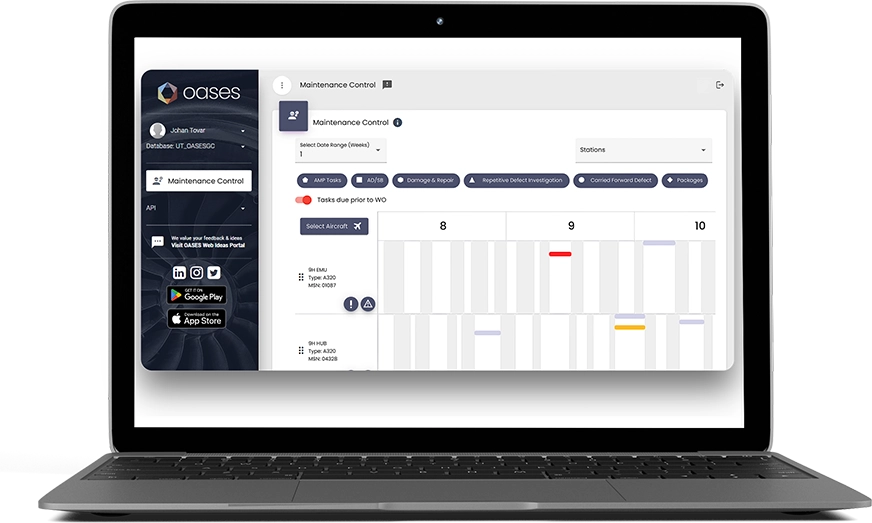

Maintenance organisations need to have a comprehensive strategy in place to manage entire fleets in accordance with tight deadlines and airworthiness regulations. Thankfully, software simplifies the process, making it easy to track scheduling, allocate engineers, manage materials, much more.

How Software Handles MRO Admin

With the increased pressure to maintain aircraft at the required pace comes a lot of admin. From invoicing to labour billing to currency control, there is a lot to manage and it can easily get out of hand if a comprehensive system is not in place to create order from chaos – especially since all of these details need to be recorded in a coherent manner for auditing purposes.

Thankfully, having an all-in-one system to keep tabs on maintenance activities provides a single source of truth. This allows for optimum oversight of maintenance management, commercial management, warranty management, and every other essential function. It also allows operators to automate many repetitive tasks, saving a great deal of time.

However, technology brings much more to the table than simple organisation.

Predictive Maintenance

As we have recently discussed, analytics, artificial intelligence, and the Internet of Things (IoT) are being used to collect and analyse vast amounts of aircraft data. This data may be used for predictive maintenance purposes, thus reducing downtime and increasing aircraft availability.

Predictive maintenance in aviation is relatively new compared to its use in other industries such as manufacturing. So, while not as much research has been done in this area, the existing data indicates that maintenance budgets are reduced by 40% thanks to this approach.

In addition, the real-time monitoring of data can ensure that the required personnel are in the right place faster. For example, when data is reviewed while the aircraft is in flight, maintenance teams can have an engineer ready at the destination to check on any defects discovered.

Click to discover more about how to maintain safe yet profitable operations for MRO.

Data Management

Proper data management is needed if data is to be of any use, and that’s where systems such as OASES come into play. The raw data generated by every flight needs to be aggregated, stored, and structured – and its quality and security must be handled in a compliant way.

All of the above needs to happen quickly due to the pace at which the industry operates. A centralised location for data (such as private cloud storage) not only makes data processing efficient and therefore faster, but it also ensures a single source of truth and makes it easy to integrate different systems together. All the different activities that require access to data are optimised, saving a great deal of time at-scale.

Compliance

There are many ways in which MRO software can ensure compliance. For example, our Continuing Airworthiness module generates reports based on comprehensive data about defects and the condition of components. It then automatically raises a repetitive defect investigation if three events occur. This way, the scope for non-compliance is greatly reduced.

Aside from safety, our MRO software can streamline customs compliance in any territory, both inward and outward bound thanks to a robust data audit trail.

Customs information is captured when the shipment clears – no need to wait until the goods have reached the warehouse. You can also keep on top of shipments at all times, tracking their progress between warehouses or to/from a supplier.

Sustainability

The industry will need big data in order to reach net-zero CO2 emissions by 2050. Big data in aviation can help companies become more sustainable in several ways. First, data can help optimise routes and adjust other variables that affect fuel consumption. It can also point to potential problems such as leaks, ensuring that no fuel is being wasted. Airlines can also use data on their carbon emissions and purchase carbon offsets to mitigate their impact on the environment.

In Summary

Globalisation has created new challenges for aircraft maintenance such as busier schedules, cross-border compliance, and the management of complex supply chains. Despite the increased demand for air transport, there is also the challenge of sustainability – airlines need to meet net zero targets despite their expansion.

Technology is playing a vital role in addressing these challenges. MRO software streamlines maintenance management and compliance and automates a great deal of admin, while aircraft data may be harnessed for predictive maintenance purposes and optimising fuel usage.

To join the many MROs, CAMOs and airlines using state-of-the-art software to improve their safety, compliance, logistics and financial management processes, contact us today to book a demo.