Using MRO Software to Keep Aircraft Flying During the Summer Aircraft Peak Operations Period

Many airlines are creeping closer to 2019 capacity levels, with Ryanair and Indigo experiencing 30% higher capacity than in July 2019.

This summer surge gives airlines the challenge of meeting increased demand while ensuring that their aircraft remain operational and perform at optimal levels.

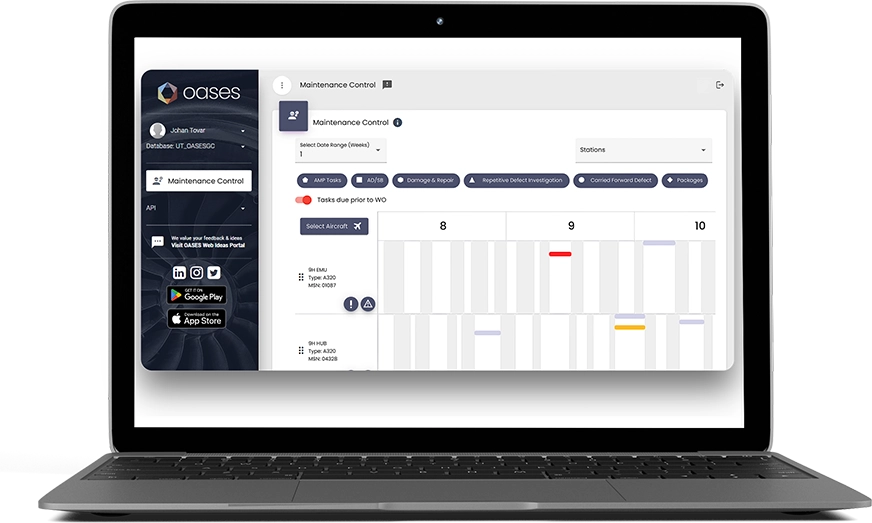

Operators rely on MRO software to manage maintenance activities during the peak operations period, ensuring that planes stay in the air where they bring profit, and not in the hangar, incurring costs.

This article explores how MRO software helps achieve maximum aircraft availability, covering some essential features, as well as integrations for getting the most out of the software.

Peak Season Operational Challenges

Higher utilisation puts additional strain on aircraft, resulting in more frequent maintenance checks. In addition, the increased number of scheduled flights limits the time available for maintenance activities between those flights. As a result, airlines must carefully plan and execute maintenance tasks within tight timeframes to minimise aircraft time and avoid disruptions to flight schedules.

The increased demand for maintenance during peak season also puts a strain on the availability of maintenance personnel, spare parts, and maintenance facilities – yet it’s vital for sufficient resources to be allocated to address maintenance needs promptly and effectively, at short notice.

Another challenging area is compliance. During peak season, when maintenance workload is high, it becomes even more burdensome to ensure that all regulatory requirements are met consistently. Airlines must have robust processes and systems in place to manage compliance and conduct thorough inspections and audits.

How MRO Software Improves Maintenance Operations

MRO software plays a vital role in ensuring aircraft meet continuing airworthiness requirements, and that schedules run on time. With MRO software, airlines can monitor the status of their entire fleet, including the maintenance history of each aircraft, upcoming tasks, and compliance information.

Maintenance Planning

Features such as work order management, task tracking, and scheduling allows maintenance teams to efficiently plan, assign, and track maintenance tasks, ensuring that all necessary inspections, repairs, and preventive maintenance activities are conducted on time.

Factors such as flight schedules and regulatory requirements are automatically accounted for, ensuring convenience and compliance at the click of a button.

Optimising Inventory Management

As mentioned, efficient inventory management becomes crucial to minimise aircraft downtime. MRO software assists by providing insights into spare parts availability, stock levels, and usage patterns. This ensures that critical spare parts are readily available – and in the required location.

Some software automates the reordering of parts, helping to avoid stockouts and reduce excess inventory, minimising delays and maximising aircraft availability.

Maintenance Forecasting

MRO software allows airlines to better plan and forecast maintenance activities, especially systems with predictive analytics capabilities that support predictive maintenance.

Thanks to its ability to aggregate large volumes of aircraft data, MRO software lets operators proactively schedule maintenance, inspections, and component replacements, minimising the impact on aircraft availability.

How MRO Software Ensures Compliance

As mentioned, during peak periods, the risk of human error rises when it comes to compliance-related documentation, simply due to the workload that staff have on their plates.

Thankfully, MRO software automates the provision of documentation and audit trails, eliminating the risk of oversight.

Some software also integrates regulatory requirements into maintenance workflows, ensuring that tasks are performed in accordance with mandates. It can also automate compliance checks, ensuring that all required inspections and certifications are completed.

Data Analytics and Reporting

Some platforms have analytics and reporting capabilities that let airlines monitor KPIs, identify trends, and make data-driven decisions about operational improvements. If an MRO platform does not have in-built analytics, it’s important that it can integrate with an external analytics platform.

Again, the volume of data generated by aircraft and maintenance management software itself is unfathomable, and to not leverage it is a waste of potential – the potential for maximising the time aircraft are in the sky, and gaining competitive advantage.

Mobile Access

For the ultimate efficiency, personnel need access to your systems no matter where they’re located. Maintenance managers can then handle their tasks from outside the office and technicians can access work orders, equipment history, manuals, and other essential details in the field. Cloud based software makes remote access possible.

MRO Software Integrations

MRO software is not a standalone solution and organisations can get the most out of it by integrating it with other mission-critical systems. With OASES, our API lets you do exactly that, so you can innovate in a way that suits your unique needs.

What other integrations benefit airlines, MROs and CAMOs when optimising maintenance operations?

Financial and Accounting Software

Integration with financial and accounting systems streamlines financial processes and enhances cost tracking and reporting related to maintenance activities. In linking the two systems, organisations can seamlessly transfer data on maintenance expenses, work orders, and inventory management, enabling accurate financial analysis.

The integration also helps ensure compliance with accounting standards and regulatory requirements, reducing the risk of errors or oversight in financial documentation.

To give a concrete example, our materials handling module lets you manage purchase, repair, loan and service exchange orders for aircraft parts and services, and all necessary forms including order and release documentation and invoices are produced automatically. Invoice data may then be passed to an accounting system for seamless management.

Cabin Management Systems

Integrating with a cabin management system (CMS) allows for efficient planning and execution of maintenance tasks specific to the cabin. Integrating these systems also improves communication between maintenance teams and cabin crew, letting staff report issues in a timely manner.

Analytics Software

As mentioned, an analytics platforms helps you get the most from your fleet data. With OASES, however, no external analytics systems are necessary – as we recently announced, our own dedicated analytics function, OASES Insights, is soon to be introduced. OASES insights comes with configurable dashboards and provides accurate timing and cost information. More information about this new release can be found here.

However, if you’re already using an analytics platform, you can connect to it using the OASES API.

Summary

MRO software is the key to effective operations during peak times, making it easy to keep up with increased maintenance and inventory demands and forecast ahead of time so you can be prepared in every moment.

It takes the complexity off your hands, making compliance easier across all operations, and the many integrations possible provide a streamlined MRO ecosystem.

So, to keep your aircraft in the sky where they make a profit – and not on the ground – invest in high quality MRO software. OASES has serves airlines across the world, helping them to get maximum value from their data and keep operations running smoothly. To book a demo, contact us today.