How Can MROs Benefit from Predictive Maintenance? And How Does Aviation MRO Software help?

Effective maintenance management is key to undisrupted flight schedules. MRO operations were traditionally reactive or preventive, focusing on scheduled maintenance or addressing issues as they arise. However, the emergence of predictive maintenance (PdM) has been transforming how airlines and MROs operate, providing significant benefits in terms of safety, cost savings, and efficiency.

PdM may reduce maintenance costs by up to 30%, and the global market for PdM is forecast to grow at a CAGR of 17% between now and 2028.

This article explores various benefits that may be driving this growth and how companies can implement PdM through cloud-hosted MRO software.

Predictive Maintenance in Aviation: How Does it Work?

PdM relies on pattern recognition and statistical analysis to predict when an aircraft component might become defective or fail.

Modern aircraft are equipped with thousands of sensors that collect data continuously. These sensors are located everywhere from the engines to the wings; from the cockpit to the brakes. In fact, an Airbus A380 can be fitted with up to 25,000 sensors and GE jet engines alone collect 5,000 data points per second.

Algorithms analyse the data collected, forecasting potential issues before they become critical. This approach is a significant departure from traditional scheduled maintenance, which relies on planning inspections and repairs at fixed intervals, regardless of the actual condition of the components.

Sensors cannot always directly provide the required data for all components. For example, consider bearings – their reliability is crucial for safety and a defect with even one of them can have disastrous consequences. However, measurements for temperature, vibration and acoustics have to be used to assess their condition.

Types of Predictive Aircraft Maintenance

In the aviation industry, PdM typically comes in one of three forms:

- Real-time diagnostics: Monitoring is conducted during flight so that repairs can be carried out on landing.

- Real-time flight assistance: Here, pilots are provided with assistance in-flight.

- Prognostics: This is about detecting potential defects/system degradation and asset management (in terms of managing component lifecycles).

Key Benefits of Predictive Maintenance in Aircraft Services

Enhanced Safety and Reliability

The most obvious, and most important benefit here is safety. Continuously monitoring the health of aircraft components ensures anomalies are detected early, allowing for timely interventions before issues escalate into safety hazards. This reduces the risk of in-flight failures. Ensuring that aircraft are always in top condition also helps MROs comply with regulatory requirements.

Optimised Maintenance Scheduling

Analysing data from multiple aircraft enables MROs to identify trends that indicate when maintenance is likely to be needed, allowing for more precise scheduling that’s convenient for both the airline and MRO provider. This reduces the impact on flight schedules and improves overall fleet availability.

Cost Savings and Efficiency

Downtime is a significant cost driver, resulting in lost revenue opportunities. Thankfully, the ability to predict failures reduces the likelihood that aircraft will be grounded unexpectedly. Not only does this maximise aircraft utility, but it also means that the high operating costs associated with unscheduled maintenance and emergency parts orders can be avoided.

PdM also helps manage the lifecycle of components more accurately. Instead of replacing a component based on a predetermined schedule, PdM allows for parts to be replaced only when the data indicates they’re nearing the end of their useful life. This minimises unnecessary replacements and extends the life of components, leading to significant cost reductions.

What’s more, this approach helps organisations maintain a more streamlined inventory. Since parts are replaced based on actual condition rather than a fixed schedule, there is less need to stock large quantities of them, reducing inventory costs and storage requirements.

Improved Resource Allocation

PdM allows for better planning and resource allocation. Knowing in advance which components need attention, MROs can allocate their workforce more efficiently, ensuring that technicians with the right skills are available when needed.

This also helps reduce the pressure on maintenance teams as they can plan their work more effectively and avoid the stress of last-minute repairs.

The Role of Cloud-Hosted MRO Software in Predictive Maintenance

Cloud based airline MRO software is a critical ingredient for establishing PdM strategies. Here’s why.

Real-Time Data Collection and Analysis

Cloud based MRO software enables real-time data collection, allowing for continuous monitoring. On the other hand, legacy systems may not be able to handle the volumes of data that today’s aircraft transmit. Some systems also have built-in condition monitoring and PdM features.

Scalability and Flexibility

Cloud-based systems can easily scale to accommodate increased data volumes and additional users, ensuring that PdM capabilities remain robust and effective – no matter the size an organisation or its fleet, nor the number of sensors constantly transmitting data.

Better Inventory Management

Effective inventory management goes hand in hand with predictive maintenance strategies. Modern, cloud based software provides flexible tools that automate aspects of inventory management, such as automatic re-ordering when stock levels are low.

Enhanced Collaboration and Communication

PdM relies on effective communication and collaboration between various stakeholders, including airlines, MROs, and parts suppliers. Cloud MRO software facilitates this collaboration by providing a centralised platform where all parties can access the same information in real time. As such, it ensures that everyone is on the same page when it comes to maintenance tasks.

Implementing Predictive Maintenance in Aviation

Implementing predictive maintenance requires careful planning and investment in the appropriate technologies. Here are some essential steps for organisations looking to adopt such an approach.

Develop a Data Management Strategy

A comprehensive data management strategy is essential for the successful implementation of PdM. MROs should focus on several key areas:

- Data collection: Establish protocols for collecting data from the required sources. This data should be comprehensive and cover all relevant aspects of aircraft performance and maintenance history.

- Data processing and storage: Implement robust systems for processing and storing the collected data. This may involve using cloud-based solutions that provide scalable storage and easy access to data for analysis.

- Data analysis: Use analytics tools to extract meaningful insights from the data.

- Data security: Ensure that data security measures are in place to protect sensitive information. This includes using encryption, access controls, and conducting regular audits to safeguard against breaches.

Train Staff

To effectively implement predictive maintenance, it is vital to equip staff with the necessary skills and knowledge. Provide training on the specific technologies used in PdM and educate staff on the broader implications of this strategy for safety and operational efficiency. Understanding how it contributes to overall performance can lead to greater buy-in and commitment from the team.

Collaborate with Stakeholders

The successful implementation of PdM requires collaboration among various stakeholders, including airlines, MROs, parts suppliers, and regulatory bodies. Key collaborative efforts include:

- Joint planning: Work together to develop a shared vision for PdM that aligns with the goals of all stakeholders. This may involve setting common objectives and performance metrics.

- Information sharing: Establishing protocols for the timely exchange of relevant data and insights is crucial. This improves decision-making processes, allowing stakeholders to respond effectively to challenges and opportunities.

- Feedback mechanisms: Establish avenues to gather feedback from all parties involved. Regularly review the outcomes of PdM initiatives and adjust strategies based on stakeholder input to ensure continuous improvement.

Conclusion

Predictive maintenance is transforming aviation maintenance operations, offering a more proactive and efficient approach. To recap, its benefits include enhanced safety and efficiency; cost reduction (through managing parts lifecycles and reducing downtime); better inventory management; and more effective allocation of personnel.

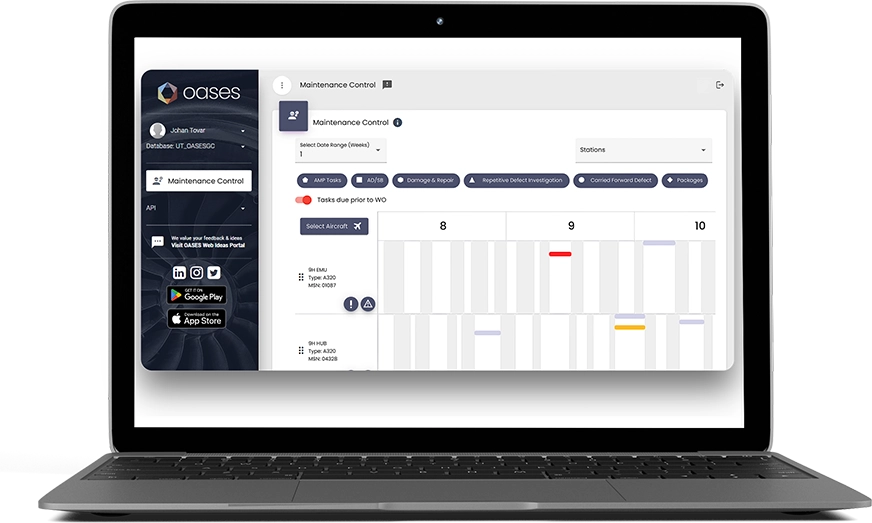

OASES provides innovative solutions for more than 130 aviation organisations around the world, including national carriers, large third-party maintenance providers, and independent operators. To see for yourself how they benefit, contact us today to request a demo.

To learn more or book an OASES demo, contact us today

For organisations looking to ascend to new heights of operational excellence, contact us today to book a demo.