In Maintenance, Repair, and Overhaul (MRO), efficient materials management is crucial for ensuring safety, minimising downtime, and reducing costs. Of course, materials management has become more challenging in recent years due to global supply chain challenges and rising costs, however.

The Oliver Wyman 2023 MRO Survey revealed that, while production has increased since the pandemic, around three quarters of respondents expect supply chain challenges to persist for several years. Strong fleet growth between now and 2033 (from 31,000 to 42,700 aircraft) will add to the challenge.

Such issues inspire organisations to reduce costs, maximise efficiency, and stay a few steps ahead when it comes to acquiring materials, ensuring what they need is always available – despite longer lead times.

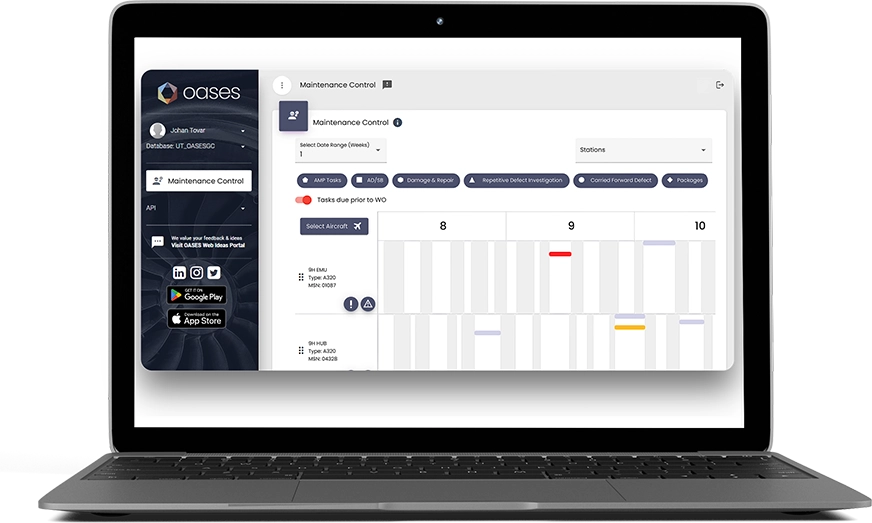

Thankfully, OASES’ Material Management module makes this possible. It also integrates with other OASES modules (including Line Maintenance), ensuring consistent data flow across departments, streamlining your broader operations. Read on to learn exactly how it helps in maintaining a safe fleet while reducing costs.

Features of Our MRO Software Material Management Module

Seamless Order Control

The module has robust order control capabilities, handling the management of purchase, repair, loan, and service exchange orders for aircraft parts and services, as well as commercial orders for non-aircraft goods.

This all-encompassing approach simplifies the ordering process, ensuring that all required forms – including orders, serviceable tags, and release documentation – are generated automatically. These documents can then be emailed, printed to PDF, or sent to thermal transfer printers.

The system updates orders, stock, and replenishment levels, and batch and serial number histories in real-time, maintaining a seamless flow of information.

In addition, the invoice-passing routines ensure payments are authorised only when they meet predefined business rules.

This level of control and automation significantly reduces the manual workload, mitigates errors, and enhances efficiency.

Efficient Stock Control

How does the module ensure efficient stock control?

Continuous Monitoring

It continuously monitors stock levels, keeping detailed records of costs, component locations, and usage histories. This comprehensive tracking supports informed decision-making and ensures that the right materials are available when needed.

Comprehensive Batch and Serial Traceability

Batch and serial number traceability is vital for maintaining an accurate and reliable audit trail of all materials.

The module ensures that every transaction is logged, providing a complete history of each item’s origin, usage, repair history, and current stock location. Users with the appropriate system permissions can easily access this information, which enhances accountability and traceability.

Streamlined Loan Control

Managing loaned parts can be a cumbersome aspect of materials management. The module addresses this by automatically logging all parts that are loaned in or out through the parts issued and received facilities. This feature provides improved control over this often-overlooked area, reducing the risk of lost or unreturned parts.

The system also accommodates multiple ownership scenarios, automatically updating ownership records as needed. This ensures that all parts are accurately tracked regardless of their ownership status, further minimising losses and discrepancies.

Accurate Tool Control

In addition to managing materials, the module offers robust tool control features, ensuring that tools are efficiently and accurately managed and tracked.

Tools can be issued to and received by individual staff members, and RFID tagging can automate this process. This capability extends to locating tools within the hangar, which reduces the time spent searching for equipment and ensures that maintenance tasks proceed smoothly.

Conclusion

Our Material Management module is an indispensable tool for airlines and MRO operators, offering comprehensive features that streamline inventory and materials control.

It has everything necessary to effectively manage material demand, ensuring maintenance operations run smoothly.

Its integration with other OASES modules ensures seamless data consistency and automation across departments, resulting in significant cost and efficiency savings.

To see the materials management module – and the rest of OASES’ features in-action – get in touch to request a demo.

To learn more or book an OASES demo, contact us today

For organisations looking to ascend to new heights of operational excellence, contact us today to book a demo.