Drones and Artificial Intelligence are revolutionising the way MRO services are delivered, and the use of AI for predictive maintenance and business process automation makes many facets of MRO operations more efficient and cost-effective. This is very much needed due to the shortage of aviation maintenance technicians.

These emerging technologies are having a profound impact on the industry, as they help to maintain safe yet profitable operations for MRO. Some estimates even state that drones reduce Aircraft on Ground (AOG) time by as much as 90% – can you imagine the customer satisfaction that follows when unplanned maintenance is prevented and aircraft are out of service for a fraction of the time?

How Are Drones Used in MRO?

AI-powered drones use computer vision technology inspect aircraft, identify potential issues, and provide high-resolution images showing much greater detail than a technician would see with the naked eye. Visual feedback can also be in the form of 3D models, and drones may be equipped with thermal cameras and mechanical analysers as well.

Manual visual inspections are extremely time-consuming and costly. In an already struggling economy, automating the process has been a welcome innovation for many CAMO and MRO organisations. After all, it can take a full day or more to complete a visual inspection of a large aircraft but using drones, it can be done in a matter of hours. The result? More time in-service and less costs for hangar space. (Although, some manufacturers have developed drones that can perform inspections outdoors.)

Drones also eliminate the risks associated with technicians working at heights and saves the time that would have been spent putting together and disassembling scaffolding, harnesses, and other safety equipment. They can also inspect an aircraft thoroughly without getting tired and missing details like a human might, making the maintenance process more accurate; engineers can then direct their focus to analysing defects and making informed assessments on what maintenance is required.

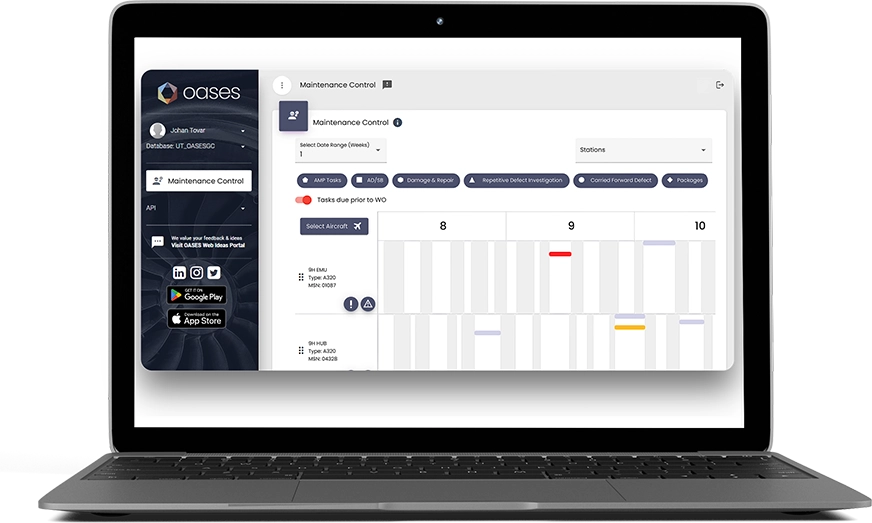

Drones also provide compliant inspection data which can be streamlined for reporting purposes with software such as OASES. This data is reliable and consistent, every time – it is objective evidence of the aircraft status, which is essential when it comes to warranty claims. The provision of this data also reduces the time spent manually taking photographs, writing reports ,and so on.

Drones for Checking Peeling Paint

Certain types of aircraft are known to have issues with peeling paint due to UV damage and the inability of paint to adhere well to titanium fasteners. While not a safety concern during flight, it can be worrying for commercial airline passengers that notice the tape that’s been applied to the peeling paint to prevent it from getting worse.

In addition, technicians may be at risk when applying the tape; there was an alert by the FAA back in 2020 about the possibility of vacuum-based fall-arrest protection system failure as a result of paint peeling from the surface of the aircraft’s upper wing. Thankfully, drone inspections are a rapid way to thoroughly monitor the location and progression of peeling.

Repair Robots

As well as using drones for inspections, various types of robots are now being used to carry out certain types of repairs. For example, Lufthansa Technik have been using robotics to repair parts of the fuselage and wing structures. Given that a large proportion of aircraft skin consists of fibre-reinforced composites – and that damage to this material is difficult to detect and repair – automating this process saves a great deal of time.

The airline have also discussed how their robots can repair scarf joints. After scanning the damage, the robot calculates the shape of the scarf joint and milling path, removes the damaged material, and the repair layers are inserted, bonded, and cured.

Using automation in this way supports the remote maintenance of aircraft, and the specifications gathered from the initial repair allows for easy replication of the part in future.

The Role of Artificial Intelligence in MRO

Predictive Maintenance

Thanks to the combination of Machine Learning and the deployment of sensors, data models are able to predict faults ahead of time, ensuring that they can be dealt with before safety is compromised. Again, this reduces the time and cost associated with traditional maintenance operations. In fact, the US army, airforce, and navy have been investing heavily in predictive maintenance and other forms of AI due to cost savings involved.

Digital Twins

Digital twin technology is also being adopted in many industries, from aerospace to manufacturing, and can be used for predictive maintenance purposes, among other use-cases. A digital twin is a virtual replica of an asset, process, product, or system, generated from data collected through various sensors and in some cases, drones. Simulations can also be run in order to determine how an asset will perform under specific conditions.

Analytics

AI is the foundation of analytics software which is used to optimise a broad array of business operations, such as cost management, resource allocation, materials logistics, warehouse management, warranty management, and much more.

In Summary

Drones continue to grow in prominence in MRO operations due to their impact on time and cost savings. Computer vision technology allows high-resolution images to be available for engineers to analyse and 3D models can also be created from the data gathered by drones. The data collected is consistent and objective which not only improves accuracy but helps in the case of warranty management.

Drones allow visual inspections to be carried out in a matter of hours rather than days, vastly reducing AOG time – all without risking technician safety. Some airlines are not stopping at inspections – they are also using robots to automate maintenance tasks, as we saw with Lufthansa Technik.

As for AI, some use cases include predictive maintenance, digital twin technology, and analytics for improving business processes. Combined, these innovative technologies are transforming MRO and improving outcomes for all stakeholders.

The data collected from aircraft are only as useful as the systems in place to manage it. OASES provides a unified, cloud based MRO platform where all modules access data in a centralised manner. From continuing airworthiness to line maintenance to materials management, all aspects of fleet maintenance are covered. To discover how our software can eliminate waste from your MRO processes, get in contact today.

To learn more or book an OASES demo, contact us today

For organisations looking to ascend to new heights of operational excellence, contact us today to book a demo.