Bracing for Turbulence: How Airline MRO Software Mitigates Risks Amidst Global Financial Uncertainties

The current global landscape is marked by financial instability, fuelled by geopolitical tensions and economic unpredictability, leaving the aviation industry navigating a storm of challenges.

Amidst these uncertainties, airlines are turning to innovative solutions to mitigate risks and maintain operational resilience. Gaining more control in these areas gives organisations the tools they need to adapt and stay competitive – despite the economic situation.

In this article, we review the latest challenges the industry is facing and explore how MRO software mitigates risk and protects profits.

Current Challenges Facing the Aviation Industry

Despite recovering from the struggles of the last few years and the ongoing pressure to meet climate targets, the aviation industry continues to face new challenges.

The Israel-Hamas War

In the three weeks following the attack on 7th October, international flight bookings dropped by five percentage points, according to data by ForwardKeys. International arrivals to Middle Eastern countries including Israel, Saudi Arabia, Jordan and Lebanon reduced by 26 percentage points during that period, and routes originating in the Americas were most affected.

The Middle East has a great deal of air traffic overall, and the Israel-Hamas war is lengthening flight times for affected routes as airlines avoid the risk of flying too close to the region. Of course, this is affecting fuel usage as well – and the volatility in fuel prices due to the conflict adds another layer of unpredictability.

Supply Chain Disruptions

Disrupted supply chains are affecting the availability of spare parts, crucial for regular maintenance operations. Issues pertain to the scarcity of raw materials due to geopolitical tensions, and therefore, long lead times.

Inflation

Inflation has increased the cost of materials and labour, compounding the aforementioned supply chain shortages, and has also led to labour shortages. A shortage of US pilots has also been forecast, the deficit expected to reach 17,000 in 2024 and 24,000 in 2026.

Rising fares threaten demand and may affect profitability in the coming years, despite certain airlines such as Ryanair seeing a record-breaking summer season.

Finally, foreign exchange rate fluctuations directly impact operational costs, making financial planning more complex in turbulent times such as these.

To contest with the challenges above, airlines need to be agile and ready to respond at a moment’s notice. And that’s what MRO software is for.

What is MRO Software?

Maintenance, Repair, and Operations (MRO) software in aviation is a specialised tool designed to streamline and enhance the efficiency of aircraft maintenance processes. It helps in managing every aspect of maintenance operations, including:

- Inspections

- Maintenance scheduling and tracking

- Work order management

- Forecasting maintenance requirements

- Inventory and materials management

- Warranty management

- Financial operations including invoicing and labour cost management

- Customs tracking

- Compliance

- Reporting on all of the above

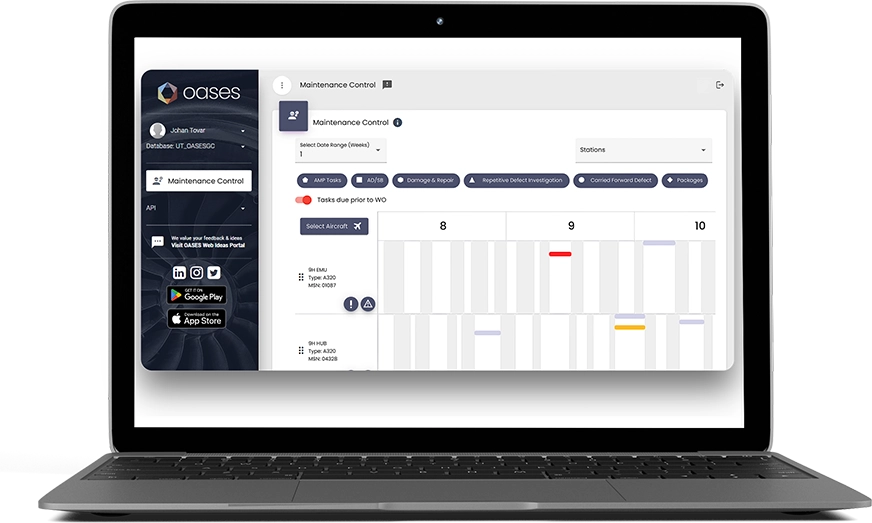

Modern, cloud based MRO software uses the huge volumes of in-flight data to inform decisions regarding all the operational areas mentioned above. The best MRO software also provides analytics tools with data visualisation capabilities.

MRO software is a must-have in the best of times – but how does it help in the worst?

How Does MRO Software Mitigate Risk?

Maintenance is one of the most significant costs for airlines. Whilst your organisation can’t control the price of fuel or raw materials, there are costs you can control, and MRO software enables you to do so. This puts you in a position to counteract rising costs in other areas and protect your margins.

Materials and Inventory Management

With supply chain challenges ongoing, it’s vital to keep your finger on the pulse when it comes to inventory. One of the most significant advantages of MRO software is its ability to optimise inventory management based on real-time needs, ensuring that you can maintain operations without unnecessary delays.

It also helps reduce inventory costs and facilitates automatic shortage management, ensuring you always have the optimum amount of stock.

Warranty Management

With inflation driving up costs, you want to claim back every expense you can. That’s why improving your warranty management processes with a view to win more claims is essential.

Our solutions feature a Warranty Management module which automates the admin involved with claims and increases your chances of success.

It automatically identifies and claims warranty on any parts that enter stores as unserviceable – and when necessary, refers the case to the warranty team for assessment if the decision requires further input. In addition, if more than one warranty term applies to a part, it will use the one most likely to lead to a successful claim.

The module has a reporting feature which can be leveraged to further drive success. For example, teams can discover which vendors or repair stations have a record of poor performance and seek to resolve the issues.

Predictive Maintenance

MRO software plays a crucial role in optimising maintenance strategies, directly impacting the financial health of an organisation by reducing overall maintenance costs and safeguarding profits.

One of the key strengths of this software is its ability to minimise downtime, a significant cost factor for any operation. Downtime not only involves direct repair costs but also results in lost productivity and revenue.

MRO software achieves this through predictive maintenance. Unlike traditional reactive approaches, predictive maintenance uses data analysis, machine learning, and real-time monitoring to anticipate potential issues before they develop into significant problems.

It does so by analysing patterns in equipment performance, and identifying early warning signs of wear or failure, which enables organisations to proactively perform maintenance tasks at opportune times, avoiding the disruption and expense of unexpected equipment breakdowns.

Predictive maintenance often means less invasive interventions are required, reducing the frequency and scale of repairs, helping to prolong the life of components and to optimise the use of resources, including spare parts and labour – which, as mentioned, is required given the current shortages.

Real-time Analytics

When rapid adaptation is key, real-time analytics is invaluable, enabling airlines to respond swiftly to factors affecting maintenance operations – whether that’s scheduling changes or rerouting flights away from conflict zones and, in turn, reassigning maintenance personnel.

Analytics provides data-driven decision support from runway to boardroom . It helps inform decisions about everyday operations (and details their financial implications) as well as high-level strategy, so you can use the wealth of data at your disposal to your advantage.

Conclusion

From an operational standpoint, geopolitical conflicts lead to route disruptions, demanding quick adaptations in planning and execution. Fluctuations in passenger demand, driven by global events, present another hurdle, as do variations in fuel costs.

In addition, the industry must continually adapt to evolving compliance standards, adding to the already complex operational landscape.

In these turbulent times, MRO software provides stability for the industry, helping reduce maintenance costs on the whole and improve inventory and warranty management processes. Predictive maintenance and analytics tools provide further advantages.

For organisations looking to stay ahead despite financial uncertainties, using MRO software is an essential strategy for risk management and operational resilience. So, to gain the edge, contact us today and book a demo.